- Funktionen

- Spezifikation

- Beschreibung

- Schnellübersicht

- Video

- Anfrage

- Verwandte Produkte

Funktionen

Schnelle Details:

Größe: M2~M6

Körperform: Sechskant

Typ: Distanzstück mit Metall-Einlage

Material: nylon+brass

Oberfläche: Unbeschichtet

Spezifikation

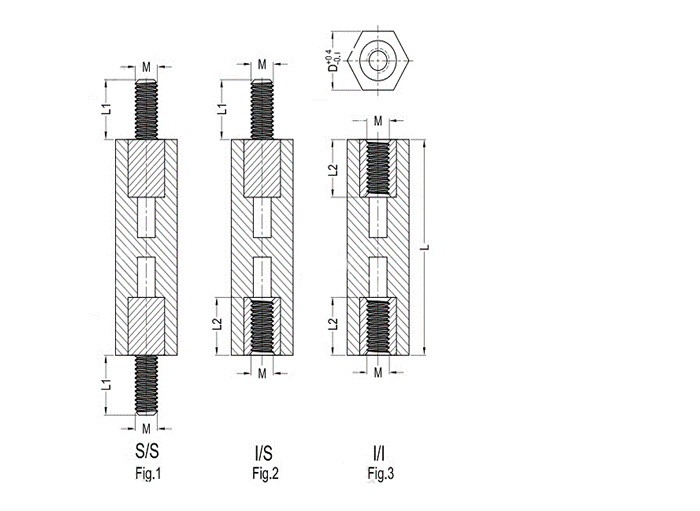

| P/Nr. | D | L | L1 | L2 | M | Abb. | |

| M3-6-14.9-S1/S1 | 6.0 | 14.9 | 8.1 | / | M3 | 1 | |

| M3-6-14.9-11/S1 | 6.3 | 2 | |||||

| M3-6-14.9-1/11 | 1 | 3 | |||||

| M3-6-42-S1/S1 | 42.0 | 8.1 | / | 1 | |||

| M3-6-42-I1/S1 | 6.3 | 2 | |||||

| M3-6-42-1/I1 | / | 3 | |||||

| M3-6-44.9-S1/S1 | 44.9 | 8.1 | / | 1 | |||

| M3-6-44.9-1/S1 | 6.3 | 2 | |||||

| M3-6-44.9-1/I1 | / | 3 | |||||

| M3-6.4-15-S2/S2 | 6.4 | 15.0 | 6.0 | 1 | 1 | ||

| M3-6.4-15-I1/S2 | 6.3 | 2 | |||||

| M3-6.4-15-1/|1 | / | 3 | |||||

| M3-6.4-18-S2/S2 | 18.0 | 6.0 | / | 1 | |||

| M3-6.4-18-|1/S2 | 6.3 | 2 | |||||

| M3-6.4-18-|1/|1 | / | 3 | |||||

| M3-6.4-20-S2/S2 | 20.0 | 6.0 | / | 1 | |||

| M3-6.4-20-|1/S2 | 6.3 | 2 | |||||

| M3-6.4-20-1/11 | 1 | 3 | |||||

| M3-6.4-22-S2/S2 | 22.0 | 6.0 | / | 1 | |||

| M3-6.4-22-|1/S2 | 6.3 | 2 | |||||

| M3-6.4-22-|1/S3 | 10.0 | ||||||

| M3-6.4-22-|1/|1 | I | 3 | |||||

| M3-6.4-25-S2/S2 | 25.0 | 6.0 | I | 1 | |||

| M3-6.4-25-I1/S2 | 6.3 | 2 | |||||

| M3-6.4-25-1/11 | 1 | 3 | |||||

| M3-6.4-28-S2/S2 | 28.0 | 6.0 | / | M3 | 1 | ||

| M3-6.4-28-I1/S2 | 6.3 | 2 | |||||

| M3-6.4-28-|1/11 | / | 3 | |||||

| M3-6.4-30-S2/S2 | 30.0 | 6.0 | / | 1 | |||

| M3-6.4-30-11/S2 | 6.3 | 2 | |||||

| M3-6.4-30-|1/|1 | / | 3 | |||||

| M3-6.4-36-S2/S2 | 36.0 | 6.0 | / | 1 | |||

| M3-6.4-36-I1/S2 | 6.3 | 2 | |||||

| M3-6.4-36-11/11 | / | 3 | |||||

| M3-6.4-38-S2/S2 | 38.0 | 6.0 | 1 | 1 | |||

| M3-6.4-38-|1\/S2 | 6.3 | 2 | |||||

| M3-6.4-38-|1\/11 | / | 3 | |||||

| M3-6.4-40-S1\/S1 | 40.0 | 8.1 | / | 1 | |||

| M3-6.4-40-I1\/S1 | 6.3 | 2 | |||||

| M3-6.4-40-S2\/S2 | 6.0 | / | 1 | ||||

| M3-6.4-40-I1\/S2 | 6.3 | 2 | |||||

| M3-6.4-40-|1\/1 | / | 3 | |||||

| M3-6,4-41-S2\/S2 | 41.0 | 6.0 | / | 1 | |||

| M3-6.4-41-|1\/S2 | 6.3 | 2 | |||||

| M3-6.4-41-|1\/11 | / | 3 | |||||

| M3-6.4-45-S2/S2 | 45.0 | 6.0 | / | 1 | |||

| M3-6.4-45-|1/S2 | 6.3 | 2 | |||||

| M3-6.4-45-I1/11 | / | 3 | |||||

| M4-7.8-14.9-S1/S1 | 7.8 | 14.9 | 8.1 | / | M4 | 1 | |

| M4-7.8-14.9-11. S1 | 6.3 | 2 | |||||

| M4-7.8-14.9-11/11 | 1 | 3 | |||||

| M4-7.8-20-S1/S1 | 20.0 | 8.1 | / | 1 | |||

| M4-7.8-20-11/S1 | 6.3 | 2 | |||||

| M4-7.8-20-I1/11 | 1 | 3 | |||||

| M4-7.8-25-S1/S1 | 25.0 | 8.1 | 1 | 1 | |||

| M4-7.8-25-11/S1 | 6.3 | 2 | |||||

| M4-7.8-25-11/11 | 1 | 3 | |||||

| M4-7.8-30-S1/S1 | 30.0 | 8.1 | / | 1 | |||

| M4-7.8-30-I1IS1 | 6.3 | 2 | |||||

| M4-7.8-30-11/11 | 1 | 3 | |||||

| M4-8-10-S2/S2 | 8.0 | 10.0 | 6.0 | I | 1 | ||

| M4-8-10-12/S2 | 4.0 | 2 | |||||

| M4-8-10-12/12 | / | 3 | |||||

| M4-8-12-S2/S2 | 12.0 | 6.0 | / | 1 | |||

| M4-8-12-I2S2 | 4.0 | 2 | |||||

| M4-8-15-S2/S2 | 15.0 | 6.0 | / | 1 | |||

| M4-8-15-I1/S2 | 6.3 | 2 | |||||

| M4-8-15-I1/I1 | / | 3 | |||||

| M4-8-20-S1/S1 | 20.0 | 8.1 | / | 1 | |||

| M4-8-20-I1/S1 | 6.3 | 2 | |||||

| M4-8-20-S2/S2 | 6.0 | / | 1 | ||||

| M4-8-20-11/S2 | 6.3 | 2 | |||||

| M4-8-2041/01 | / | 3 | |||||

| M4-8-22-S2/S2 | 22.0 | 6.0 | / | M4 | 1 | ||

| M4-8-22-I1/S2 | 6.3 | 2 | |||||

| M4-8-22-11/11 | / | 3 | |||||

| M4-8-25-S1/S1 | 25.0 | 8.1 | / | 1 | |||

| M4-8-25-I1/S1 | 6.3 | 2 | |||||

| M4-8-25-I1/11 | / | 3 | |||||

| M4-8-27-S1/S1 | 27.0 | 8.1 | / | 1 | |||

| M4-8-27-I1/S1 | 6.3 | 2 | |||||

| M4-8-27-S2/S2 | 6.0 | 1 | 1 | ||||

| M4-8-27-I1/S2 | 6.3 | 2 | |||||

| M4-8-27-11/01 | / | 3 | |||||

| M4-8-30-S1/S1 | 30.0 | 8.1 | I | 1 | |||

| M4-8-30-I1/S1 | 6.3 | 2 | |||||

| M4-8-30-S2/S2 | 6.0 | / | 1 | ||||

| M4-8-30-11/S2 | 6.3 | 2 | |||||

| M4-8-30-11/11 | / | 3 | |||||

| M4-8-36-S2/S2 | 36.0 | 6.0 | / | 1 | |||

| M4-8-36-I1/S2 | 6.3 | 2 | |||||

| M4-8-36-1/11 | / | 3 | |||||

| M4-8-40-S2/S2 | 40.0 | 6.0 | / | 1 | |||

| M4-8-40-I1/S2 | 6.3 | 2 | |||||

| M4-8-40-1/11 | / | 3 | |||||

| M4-8-45-S2/S2 | 45.0 | 6.0 | / | 1 | |||

| M4-8-45-I1/S2 | 6.3 | 2 | |||||

| M4-8-45-1/11 | / | 3 | |||||

| M4-8-50-S1/S1 | 50.0 | 8.1 | / | 1 | |||

| M4-8-50-I1/S1 | 6.3 | 2 | |||||

| M4-8-50-11/11 | / | 3 | |||||

| M4-8-60-S1/S1 | 60.0 | 8.1 | / | 1 | |||

| M4-8-60-I1/S1 | 6.3 | 2 | |||||

| M4-8-60-1/11 | / | 3 | |||||

| M4-9.5-90-S2/S2 | 9.5 | 90.0 | 6.0 | 7 | 1 | ||

| M4-9,5-90-I1/S2 | 8.5 | 2 | |||||

| M4-9,5-90-11/11 | / | 3 | |||||

| M5-9,5-19-S4/S4 | 19.0 | 8.0 | / | M5 | 1 | ||

| M5-9,5-19-I1/S4 | 6.3 | 2 | |||||

| M5-9,5-19-S1/S1 | 10.1 | / | 1 | ||||

| M5-9,5-19-11/S1 | 6.3 | 2 | |||||

| M5-9,5-19-1/11 | / | 3 | |||||

| M5-9,5-20-S1/S1 | 20.0 | 10.1 | / | 1 | |||

| M5-9,5-20-11/S1 | 6.3 | 2 | |||||

| M5-9,5-20-I1/I1 | / | 3 | |||||

| M5-9.5-25-S1/S1 | 25.0 | 10.1 | / | 1 | |||

| M5-9.5-25-I1/S1 | 6.3 | 2 | |||||

| M5-9.5-25-I1/11 | / | 3 | |||||

| M5-9.5-40-S1/S1M5-9.5-40-11/S1 | 40.0 | 10.1 | / | 1 | |||

| M5-9.5-40-I1/I1 | / | 6.3 | 1 | ||||

| M5-9.5-45-S1/S1M5-9,5-45-11/S1 | 45.0 | 10.1 | / | 2 | |||

| M5-9.5-45-|1/|1 | / | 6.3 | 3 | ||||

| M5-9.5-50-S1/S1 | 50.0 | 10.1 | / | 1 | |||

| M5-9.5-50-I1/S1 | 6.3 | 2 | |||||

| M5-9.5-50-I1/11 | / | 3 | |||||

| M5-9,5-58-S1/S1 | 58.0 | 10.1 | / | 1 | |||

| M5-9,5-58-S4/S4 | 8.0 | ||||||

| M5-9.5-58-|1/S1 | 10.1 | 6.3 | 2 | ||||

| M5-9.5-58-1/I1 | / | 3 | |||||

| M5-9.5-58-I1/S4 | 8.0 | 6.3 | 2 | ||||

| M5-9.5-58-I1/S3 | 13.0 | 6.3 | 2 | ||||

| M5-9.5-70-I1/S1 | 70.0 | 10.1 | 6.3 | M5 | 1 | ||

| M5-9.5-70-I1/11 | / | 2 | |||||

| M5-9.5-84-S1/S1 | 84.0 | 10.1 | / | 3 | |||

| M5-9.5-84-|1/S1M5-9.5-84-|1/11 | / | 6.3 | 1 | ||||

| M5-9.5-88.2-S1/S1 | 88.2 | 10.1 | / | 2 | |||

| M5-9.5-88.2-I1/S1M5-9.5-88.2-I1.11 | / | 6.3 | 3 | ||||

| M5-9.5-90-S1/S1 | 90.0 | 10.1 | / | 1 | |||

| M5-9.5-90-I1/S1 | 6.3 | 2 | |||||

| M5-9.5-90-|1/11 | / | 3 | |||||

| M5-10-20-S2/S2 | 9.8 | 20.0 | 5.1 | / | 1 | ||

| M5-10-20-I1/S2 | 6.0 | 2 | |||||

| M5-10-20-1/11 | / | 3 | |||||

| M5-12.7-20-S1/S1 | 12.7 | 20.0 | 10.1 | / | 1 | ||

| M5-12.7-20-I1/S1 | 6.3 | 2 | |||||

| M5-12.7-20-1/11 | / | 3 | |||||

| M6-12.7-50-S3/S3 | 50.0 | 12.7 | / | M6 | 1 | ||

| M6-12.7-50-I1/S3 | 13.0 | 2 | |||||

| M6-12.7-50-I1/I1 | / | 3 | |||||

| M6-12.7-55-S3/S3 | 55.0 | 12.7 | / | 1 | |||

| M6-12.7-55-I1/S3 | 13.0 | 2 | |||||

| M6-12.7-55-|1/|1 | / | 3 | |||||

| M6-12.7-60-S3/S3 | 60.0 | 12.7 | / | 1 | |||

| M6-12.7-60-I1/S3 | 13.0 | 2 | |||||

| M6-12.7-60-|1/|1 | / | 3 | |||||

| M6-12.7-75-S1/S1 | 75.0 | 12.0 | / | 1 | |||

| M6-12.7-75-I1/S1 | 13.0 | 2 | |||||

| M6-12.7-75-|1/|1 | / | 3 | |||||

Beschreibung

Isolierter Nylon-Standoff ist darauf ausgelegt, Teile voneinander fernzuhalten und so elektrische Kurzschlüsse zu verhindern. Wir haben Nylon-Standoffs mit Metall-Einsätzen, normalerweise Messing-Einsätzen.

Weiblich-weiblicher Abstandshalter, auch als Gewindespacer bezeichnet, mit weiblichen Gewinden an beiden Enden des Teils. Diese Konstruktion ermöglicht es, einen männlichen Abstandshalter an jedem Ende zu befestigen. Sechskantflächen erleichtern den Griff während der Installation.

Männlich-weibliches Distanzstück hat einen geschraubten Stift an einem Ende, das andere Ende ist ein sechskantiger oder runder Körper mit weiblichem Gewinde, dieses Distanzstück ist für die Montage von Leiterplatten oder anderen elektronischen Komponenten vorgesehen, bei denen enge Maßtoleranzen erforderlich sind.

Runder Standoff, auch als weiblich-weiblicher Standoff bekannt, ist dazu gedacht, zwei Materialstücke zusammenzubinden.

Standoff-Typen:

Männlich-weiblicher Hexagonal-Standoff

Weiblich-weiblicher Hexagonal-Standoff-Adapter

Männlich-weiblicher runder Standoff

Weiblich-weiblicher runder Standoff-Adapter

Standoff-Material:

Mit einem Gehalt an Stahl von mehr als 0,05 GHT

Messing

Nylon

Aluminium

Kohlenstoffstahl mit Zinkschicht oder Nickelschicht.

Nylon mit Messing-Einsatz

Form des Standoffs:

Rund, sechseckig, quadratisch

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

GA

GA

UZ

UZ