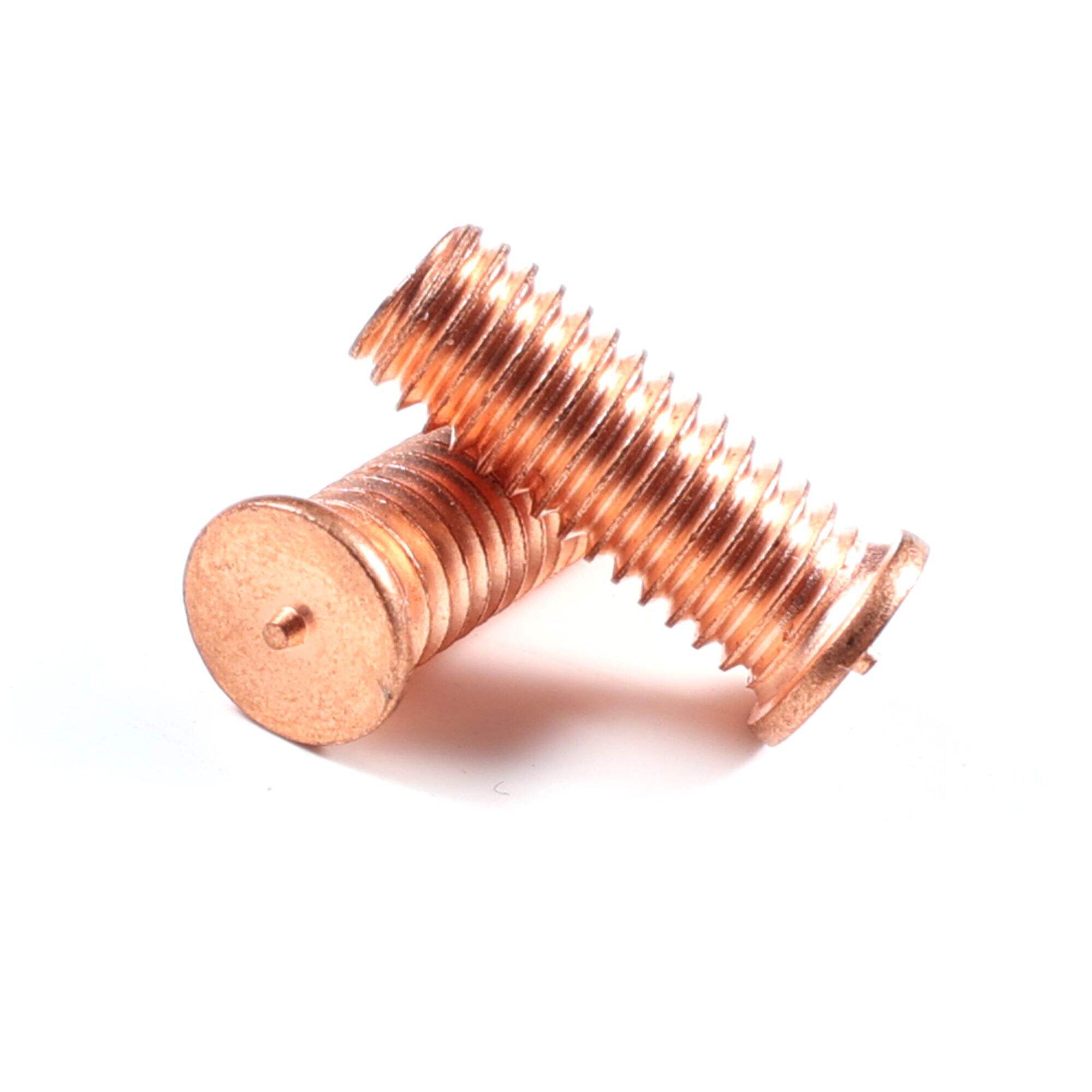

The area of application is immense for Welding Studs in the welding world. It plays a vital role in the connection of various materials fasteneding one another metal-to-metal. This type is available in numerous sizes, shapes, and styles and is the best welding electrodes among other most resilient. Pros of Welding Studs High Strength: They are the strongest among all the weldable fasteners; therefore, they are the best fasteners for the more demanding conditions. Very easy to use welding studs are extremely convenient for welding that can be fastened easily on different types of materials without the use of any other device or equipment. They are also perfect for welding as other equipment will not be needed, and the impression of the weld on the face is neat. Variety of Welding Studs There have been significant technological advancements with the invention of the welding studs. There are various welding studs types available in the world based on how one needs it. Some welding studs are specialized nuts when used in foundries, furnace that is exalted temperature industries. Installable welding studs are also available which are very convenient when it comes to DIY. How to Maximize Safety While Welding Studs Safety is the first consideration. To ensure that nearly all the welding stud installation is done correctly and safely, it is essential to follow best practices. In that case, there are excellent contaminants that can help do the job right secure. Some of the key tips to remember perspective include; * Always put on Personal Protective Equipment which may involve gloves, protection clothing, and eye protection. * Select the right welding approach for your unique material and stud.

Put proper ventilation when welding to avoid inhaling any toxic fumes/ gases. How to Use Welding Studs Step by Step The proper way of using welding studs also covers your background knowledge about the process. Read Also: Stud Welding – How To Make It Work A welding stud application will be discussed as A step-wise achievement Pick the welding studs according to a material, size, and project’s shape. Clean with a grinder and or wire brush the welding surface to remove the dirt, paint, and rust. Fit the welding machine and fix on to power level, in this regard, you want to fix. Place the welding stud above the fill of your metal piece, and place the welding gun above the same fill. Start the welding process with trigger. Keep the gun in one place for some time and it is now attached to your wall. Make sure that the ultrasonic welding’s surface is correctly cooled to prevent it from any operation issues. The Importance of Choosing the Right Quality Welding Studs For selecting welding studs, specific considerations must be taken into account: Quality and customer service are the most critical factors. Always attempt to locate a manufacturer or distributor who will provide you with a warranty on the life of their welding studs to ensure that your projects last. Furthermore, ensure that this service includes answering any questions or problems you have during the installation. The Tons of Applications of Welding Studs The application of welding stud welding can be used in various ways. The teleport offerings are perfect in several location placements. Let us show you some examples:

Construction: In the construction sector, welding studs play a key role in ensuring metal sheets and beams that need to bond are fixed together to form a concrete metal roof. Automotive: In the auto industry, automotive welding studs bond most of the car parts together during manufacture and repair places. Marine: Shipbuilding in the marine sector is wholly depedent on welding studs ensure their metal parts that give the vessel the shape bond well, which ensures their vessels are stable in water bodies. The uniqueness of the different applications and the weight of the welding studs make it possible to harness their potential in a variety of field-oriented projects to facilitate high project quality delivery.

High Strength: Welding Studs are far and away the strongest of all weldable fasteners. As such, they are ideal for highly demanding conditions and applications. Further, these are extremely easy to use welding studs and can easily be welded on different materials without any other device or equipment help. In addition, they present a clean and tidy look of the welded area as there are no visible bolts or nuts.

Over the last several years, there have been many technological advances in Welding Studs. Mostly, there are various types of welding studs that exist in the world today to suit desired needs. Specialized studs are for example nuts that can be used in industries with high temperatures, such as foundries or a furnace. In addition, some welding studs are designed to make installation easier which should be very helpful for a do-it-yourself (DIY) project.

Ultimately, safety should be paramount when working with Welding Studs. Following best safety practices is important for welding stud installation to go smoothly and securely, so be vigilant. There are some main things to remember from this perspective, and these tips include:

Wear Personal Protective Equipment (PPE) at all times, including gloves, protective clothing and eye protection.

Choose the correct welding method for your distinct material and stud.

Provide proper ventilation within the welding vicinity to avoid breathing in toxic fumes/ gases.

How to Use Welding Studs Step by Step

The proper utilization of welding studs also requires a good amount of knowledge about the process itself. Read Also : Stud Welding - How To Put Into Practice A welding stud application Accomplishment Step by step

Pick the perfect welding studs according to your material, size and shape of project.

Be sure to clean with a grinder and or wire brush the welding surface by removing any dirt, paint and rust.

Fit the welding machine and fix it onto an accurate power level for what you need.

Place the welding stud over your piece of metal, and position the welding gun right above it.

Simply keep the gun in one place for some time, and it is now fixed to your wall.

Make sure that the ultrasonic welded surface is fully cooled to avoid problems during operation.

The Importance of Choosing the Right Quality Welding Studs

Quality and customer service are paramount considerations for welding stud selection. It is recommended to always look for manufacturers or distributors that provide a guarantee on the life of their welding studs so you can be sure your projects will last. Also, make sure they offer great customer service and technical support for any questions or difficulties you might run into during installation.

Wuxi Sunny main business is manufacturing bolts nuts pin, We keep large stock of standard bolts (hex head, T head and square head), flange bolt),nuts(insert nuts, rivet nuts, hex caps nut),flat lock washers and various Quick Release Pin and indexing pin on hand. We can deliver your order within 3 working days with quick and efficient logistics.

We take pride in high quality of our items. Our fastener are made to meet the highest standards for quality and performance from our ISO certified factory and QC requirements.

We have highly skilled team comprised of technicians with over more than 20 years of experience in the fastener industry. We able customize every part of a fastener according your requirements or sample.

We had professionals sale and after-sales teams vast knowledges of fasteners and hardware, this makes our communication fast and high efficient.